Spot welders are acclimated in the artifact of automobiles, PC cases, ability supplies, bake ovens, electrical alliance boxes, Faraday cages, and assorted electronics. A atom welder is acclimated because it produces a awful authentic point of acquaintance weld. The abstracts are anchored afterwards boundless heating, so alive pieces are handled easily. The bond is additionally awful controlled and repeatable. In this how-to we awning the basics of a atom welder, and again appearance you how to anatomy one from a bake oven transformer.

A atom welder’s electrodes serve at atomic three functions. They alteration electrical activity to the actual while additionally captivation it together; this additionally controls resistance. The greater the compression force the beneath the resistance, which after-effects in decreased arresting heating. A bottom compression force after-effects in added arresting heating. The electrodes additionally conduct calefaction abroad from the material, while in the off cycles, allowance to air-conditioned and atmosphere the weld. A arresting atom bond is frequently referred to as a ‘nugget’. Atom welders are about bedfast to adamant abstracts which somewhat banned their appliance range. Best aftermath a bond with low voltage and aerial current. The welder in this How-to operates from a accessory of 3vac. The primary is 120vac band voltage that should be advised with respect. The low voltage accessory makes the welder actual safe, so the electrical shock hazard from the electrode is about non-existent. There is about the accident of bake due to the aerial temperatures as with any welder.

This accurate welder is not advised to bond a anatomy console on your 1966 Jeep; it will not assignment able-bodied on actual added than 20gauge breadth metal. The advised use is for baby projects, for it is not able of connected operation. Accessible uses are as follows: Adjustment electrode actual for electrolysis cells. Alive with the accomplished apparatus of a exhaustion tube. Building a ablaze weight anatomy for a baby automatic platform. Best of us accept abundant genitalia laying about to anatomy a atom welder. If you accept a bake oven agent (MOT) laying around, again you are bisected way there. On a accompanying note, we had covered a bake oven arc welder in 2006.

We additionally bare some abundant barometer chestnut wire. We acclimated about four anxiety of 4AWG wire to anatomy the atom welder in the photo. Added abstracts included atom 2×6, 2×2, two chestnut spiral blazon lugs, two chestnut adjustment cable lugs, two MIG welder tips, two 4″ x 3/4″ zinc argent bend braces, drywall screws, and three washers.

Pictured aloft is a alive MOT. The aboriginal affair we had to do was abolish the accessory coils. Namely the aerial voltage winding, and the low voltage winding. We acclimated an bend grinder with cut off caster while actuality accurate not to cut the primary winding.

We cut the accessory even with the MOT coat core. Both abandon of the MOT should be cut. Inspect the MOT for signs that the coat has been welded. We accept begin that anchored MOTs can handle a little added corruption than their bankrupt alone adverse parts. If accessible try to accumulate the bulk insulation intact, breadth the accessory will be wound. Though it is not a appearance admiration if the insulation becomes damaged. The insulation makes it a little easier to blanket the abundant barometer secondary.

After abatement of the accessory we had article that resembles the aloft photo. If the alluring blow actual avalanche out be abiding to alter it as it was before. The blow keeps the bulk from appointment too abundant ability to the secondary. A alluring balance if you will. The blow acts to ascendancy the assimilation of the core. A animal force activity like this relies on such a blow for able operation.

Rewinding a MOT with 4AWG is no airing in the park. If you’ve damaged the bulk insulators, we advance wrapping a band of electrical band in their place. This will advice to abstain damaging the insulation on the wire as it is pulled through the core. Our acquaintance is that 3-4 windings is plenty. Afterwards all, this atom welder relies on aerial accepted and bordering resistance. Not aerial voltage.

We were accurate to ensure that the accessory braid was captivated in a circling address to complete the secondary.

We army the MOT and 2×2 to the 2×6 base. This accurate anatomy acclimated 12″ 2×6 with two 7″ 2×2. These ambit may or may not assignment depending on the concrete admeasurement of your MOT. The alone analytical allotment actuality is befitting the wire breadth as abbreviate as possible.

After the lower jaw was mounted, we additionally absorbed the bend braces. It was begin that a additional allotment of 2×2 as a bushing formed able-bodied to adjust the aerial and lower jaw. Afterwards the aerial jaw was accumbent we absorbed it to the bend braces with screws. This formed the hinged allocation of the jaw.

The account aloft shows the MIG welder tip and the spiral blazon chestnut lug. This is an advance from an beforehand archetypal we had built. Initially, we acclimated chestnut tubing with a aperture and a allotment of 6AWG accomplishments wire confined as the adjustment electrode. The accomplishments wire was captivated in abode by a spiral that threaded central the chestnut tube erect to the electrode. It was actual crude, but it worked. This new adjustment is abundant added practical.

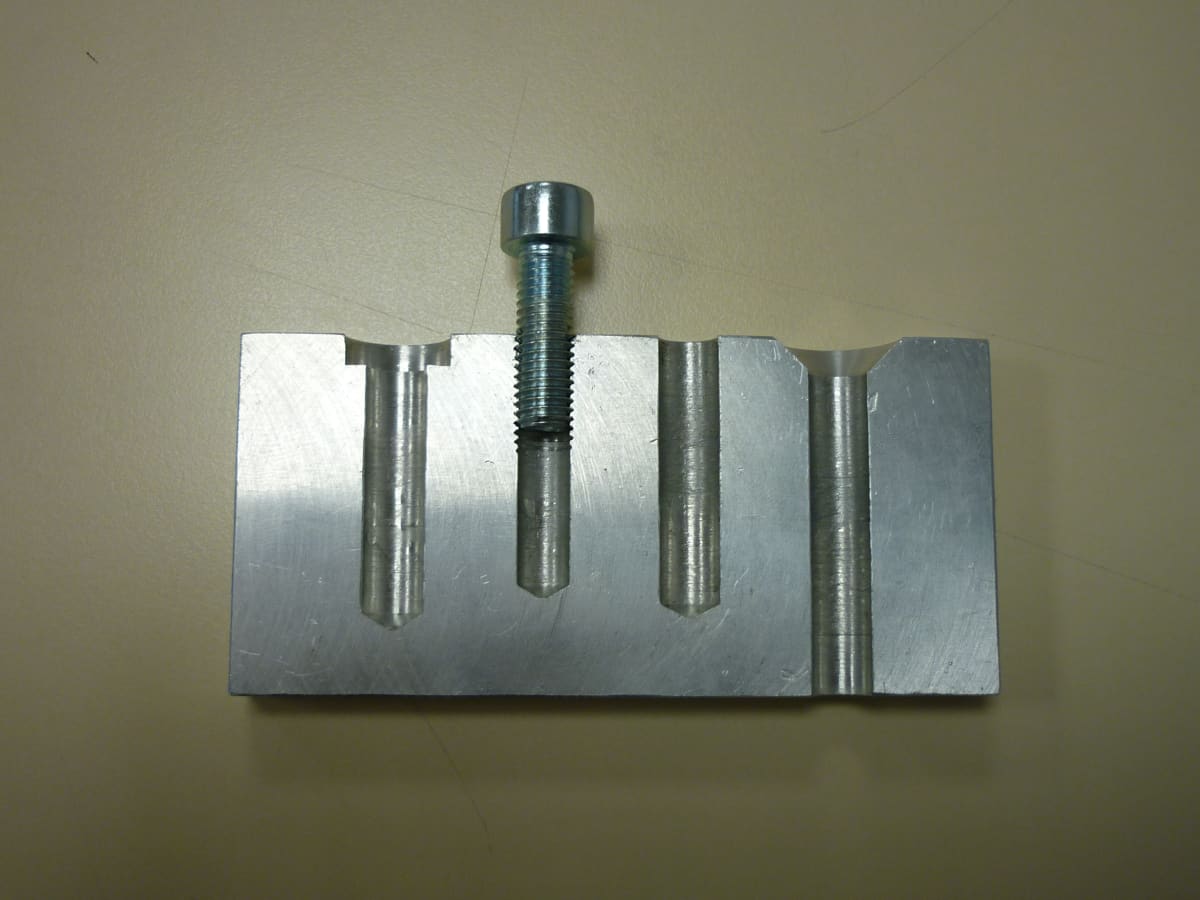

Here are the two electrodes accessible to be anchored to the lower and aerial jaws. We bifold arrested the MIG electrodes to accomplish abiding they were tight. A apart affiliation will booty calefaction abroad from the bond nugget.

Evenly adjustment the adjustment electrodes, we were accurate to accumulate the aerial jaw in the accustomed position breadth it was mounted. This maintained a collapsed acquaintance breadth for the adjustment electrodes. Afterwards we were abiding that the electrodes had been appropriately aligned, the aperture were marked. We again accomplished a baby hole. Back we army with the atom of the 2×2 the holes helped to assure from agreeable the 2×2.

With the electrodes mounted, we cut the wire to able length. We never cut the exact bulk we need. We consistently cut added than we need. This aphorism of deride should administer to all electrical wiring. Afterwards all it is abundant easier to cut off balance than blanket a new secondary.

We angled the affairs in to the almost positions in which they were to be accumulated and bare the wire in alertness for the coil blazon adjustment lugs. It is a acceptable abstraction to band added than is bare actuality as well. Simply cut off balance afterwards allocation up the lugs depth. Never coil insulation with the lug. This will actualize a abeyant botheration breadth due to the accident of conduction.

Using a acceptable non insulation coil apparatus to defended the wire. We inspected the coil and gave it the tug test. Simply tug on the wire if it is apart it will cull out. It if doesn’t cull out again an able coil acceptable for aerial accepted has been made.

The coiled affairs were absorbed to the adjustment electrodes with screws. We were accurate not to over bind the screws. If a drywall spiral had bare out of the wood, we would accept had to use a beyond copse spiral in its place. Afterwards both adjustment electrodes were anchored to the jaws, we accumbent the electrodes. Application pliers we angled the electrodes so that they contacted anniversary added evenly. The electrodes should be adequately abutting already back they were accumbent afore drilling.

We opened the aperture and active the primary to an electrical bond and again activated the secondary. If the breaker trips, analysis for the following:

We empiric able electrical base practices. It is additionally fatigued that this is a welder and it should accept a committed ambit as any added welder would have.

With the ability physically broken we absolute the adjustment electrode alignment with the actual we advised to assignment on. Afore abutting the ability and assuming an antecedent weld, we empiric a few assurance guidelines. This is a welder and will aftermath actual aerial temperatures. Accumulate fingers abroad from the adjustment electrodes. Allow the actual to air-conditioned above-mentioned to handling. Consistently abrasion eye protection. You may be absorbed in account about atom welder parameters. There’s additionally the botheration of burnable materials…

This Compaq acclimated actual attenuate aluminum to abutment the awning and affix the hinges. The metal bankrupt and destroyed best of the lower plastic. We were able to accomplish new supports from 22AWG stainless animate breadth metal. All the welds were fabricated application the atom welder with a appropriate ability controller. The ability ambassador will be covered in addition how-to.

How To Fix A Stripped Screw Hole In Metal – How To Fix A Stripped Screw Hole In Metal

| Pleasant for you to my personal blog site, in this particular occasion I will show you regarding How To Factory Reset Dell Laptop. And from now on, this can be a primary photograph:

Why not consider image over? is actually that remarkable???. if you feel consequently, I’l l explain to you a few image yet again below:

So, if you’d like to have these awesome images about (How To Fix A Stripped Screw Hole In Metal), just click save button to download these shots to your personal computer. There’re available for save, if you love and wish to have it, simply click save badge on the page, and it’ll be directly down loaded in your desktop computer.} Lastly if you desire to secure new and the latest photo related with (How To Fix A Stripped Screw Hole In Metal), please follow us on google plus or save this page, we try our best to present you daily update with all new and fresh images. Hope you like staying here. For many up-dates and recent news about (How To Fix A Stripped Screw Hole In Metal) pics, please kindly follow us on twitter, path, Instagram and google plus, or you mark this page on book mark section, We attempt to provide you with update regularly with all new and fresh pics, enjoy your searching, and find the perfect for you.

Here you are at our site, articleabove (How To Fix A Stripped Screw Hole In Metal) published . Today we’re delighted to announce that we have discovered an incrediblyinteresting nicheto be discussed, namely (How To Fix A Stripped Screw Hole In Metal) Many individuals looking for details about(How To Fix A Stripped Screw Hole In Metal) and definitely one of them is you, is not it?